Horticulture: The Dawn of a New Era

Let’s cut to the chase, without light humans are helpless.

Our eyes would be useless capsules filled with needless rods and cones, perhaps we would develop another type of sensory perception but that’s another topic for a latter discussion. Just as light is essential for human functionality, it’s even more essential for plants. The elemental particles of light, photons, are the stable food source for our green friends, who digest these particles using a chemical process called photosynthesis. I know I know this might bring flashbacks of your high school biology class, but don’t worry I’ll spare you the gory details.

I assume if you are reading this article you are in the lighting industry and are accustomed to terms such as lumens, efficacy, lux and CRI when describing the spec and quality of a light source, but in regards to horticulture, we are going to have to take a slight left turn. Throw out lumens, throw out efficacy and let’s take a deep dive into how plants see light, my apology for the pun (it was intentional).

When determining the quality of a light source (in regards to plant development) there are 4 important characteristics to understand: PAR, PPF, PPFD and photon efficiency.

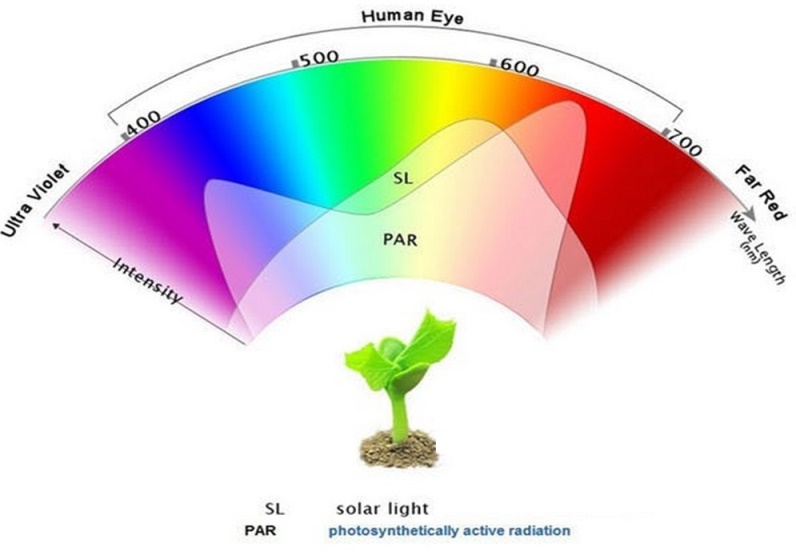

PAR (Photosynthetic Active Radiation): Defines the nature of light spectrum that specific plants need for photosynthesis to occur. The wavelength range is between 400nm-700nm. Similar to the human eye response, there are specific wavelengths that plants are more sensitive too, typically these are found in the blue-red spectrums.

PPF (Photosynthetic Photon Flux): The total amount of photons within the PAR range produced by a light source per second, which is expressed in micromoles/second (μmol/s). Similar to lumens the PPF doesn’t indicate the amount of photons actually reaching the plants. This is a good indicator of the light source’s efficiency.

PPFD (Photosynthetic Photon Flux Density): The measure of the amount of photons within the PAR range that the plant receives or the number of photosynthetically active photons that falls on a given surface each second. The PPFD is measured in micromoles per square meter per second (μmol/m2/s).

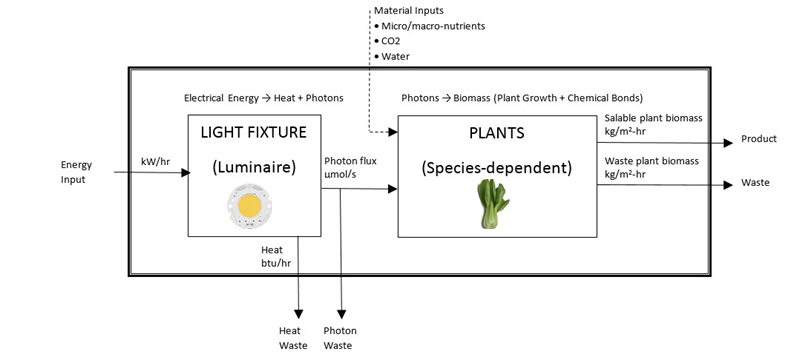

Photon Efficiency: This describes the efficiency of a light source at converting electrical energy into photons for PAR (μmol/W).

Historically, High Pressure Sodium (HPS) was the optimal light source for plant development, but with the evolution of LED technology (higher performance and lower costs), more and more growers are now transitioning their light source to LED. Here are some of the benefits of transitioning to LED technology:

1) Reduced electrical and thermal loads

- Higher yields per watt

- Greater flexibility in fixture design (reduced heat sync costs)

- Lower system costs

- Lower HVAC costs

2) Greater Design Flexibility

- Vertical farming integration

- Secondary optics

- Unique fixture designs (SMD layout patterns, COB integration)

3) Tunable Spectrum

- Traditional light sources only offer static spectrums

- LED technology provide ability for custom spectrums (flexible to meet specific plant requirements and phases of growth)

4) Lifetime and Reliability

- LEDs provide longer life times than traditional light sources (greater ROI and reduced maintenance/ service costs)

- LEDs provide greater lumen maintenance over time

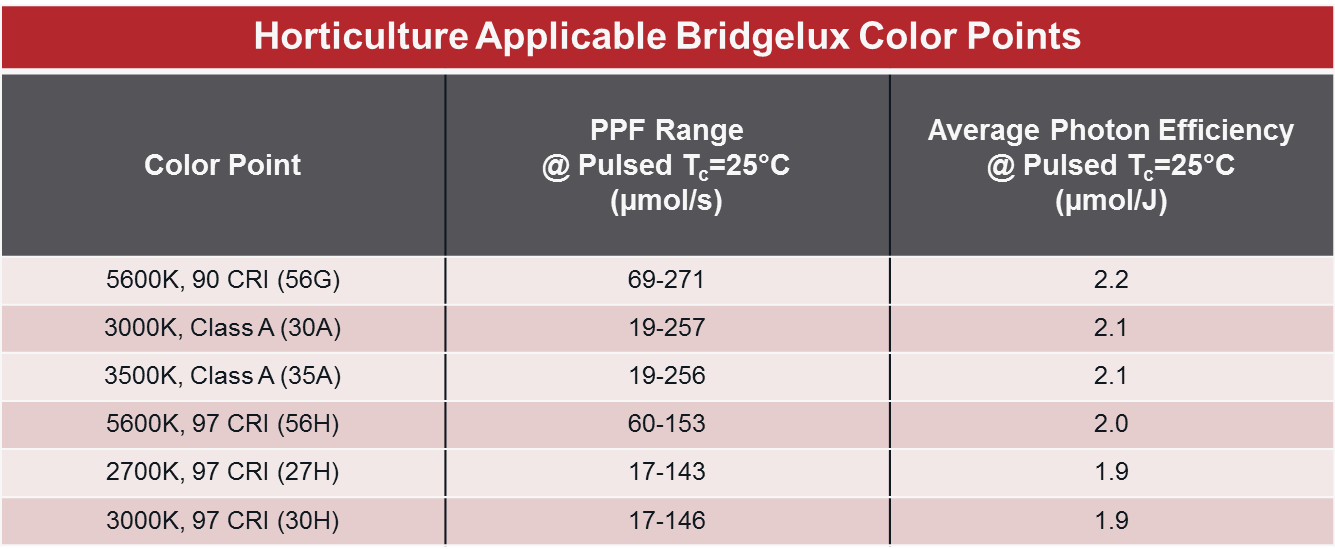

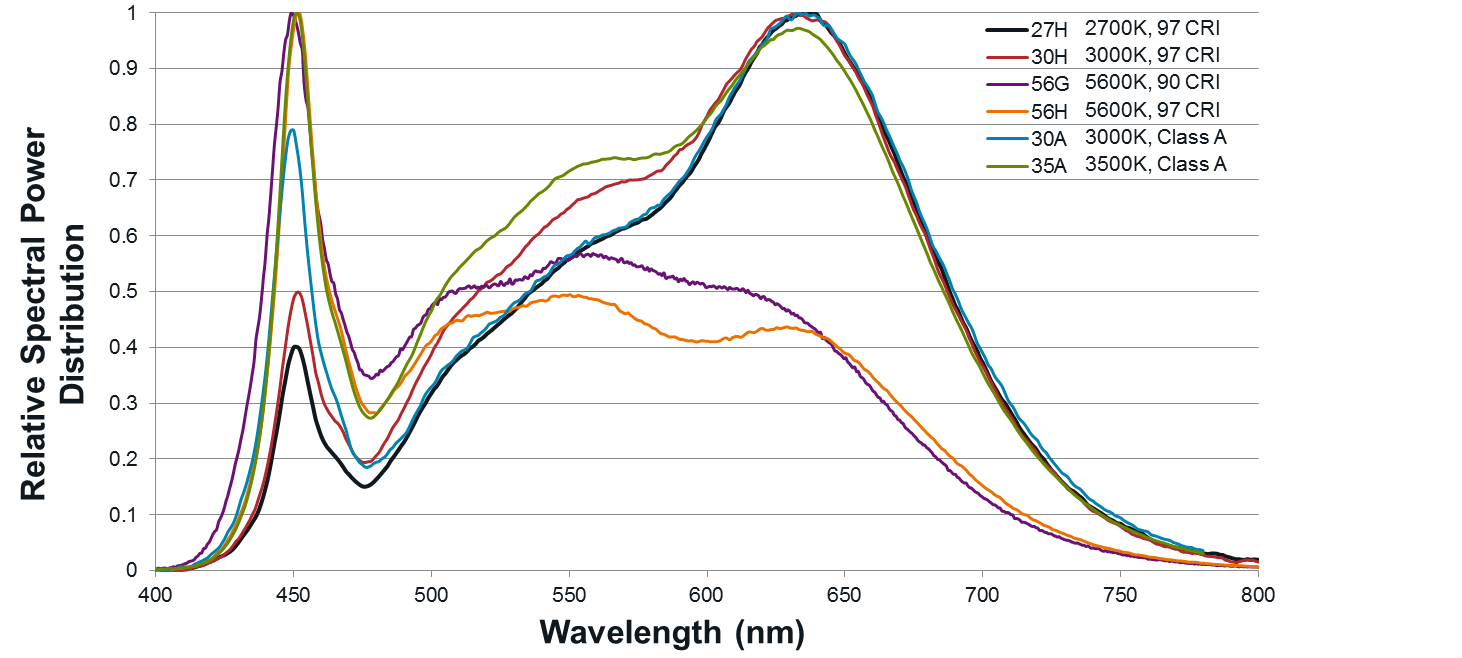

Bridgelux offers color points optimal for all stages of plant growth with leading PPF, photon efficiency and spectra, our LED Chip-on-Board (COB) technology is easily integrated into a diverse range of fixture applications including high bays, flood lights and canopy lights.

The table and graph below outline Bridgelux’s color points tailor made for horticulture applications.

Please contact your sales representative for further information on our LED COB technology and visit our Product Simulator tool for further specifications.